The Aluminum Association holds the global register of all aluminium alloys, and the association has recently accepted the A6061-RAM2 from Elementum 3D as alloy 6A61.50. This is great news for the manufacturing community involved in 3D printing of 6061 alloy. Receiving the AA’s endorsement is an assurance of A6061-RAM2’s quality and printability.

For decades, AM users and potential users have desired a wider selection of reliable, high-performance aluminium alloy feedstocks, and Elementum 3D are amongst those leading the advancement of metal AM alloy materials. A6061-RAM2 has been available commercially since 2018 and can be purchased on their website or by contacting us.

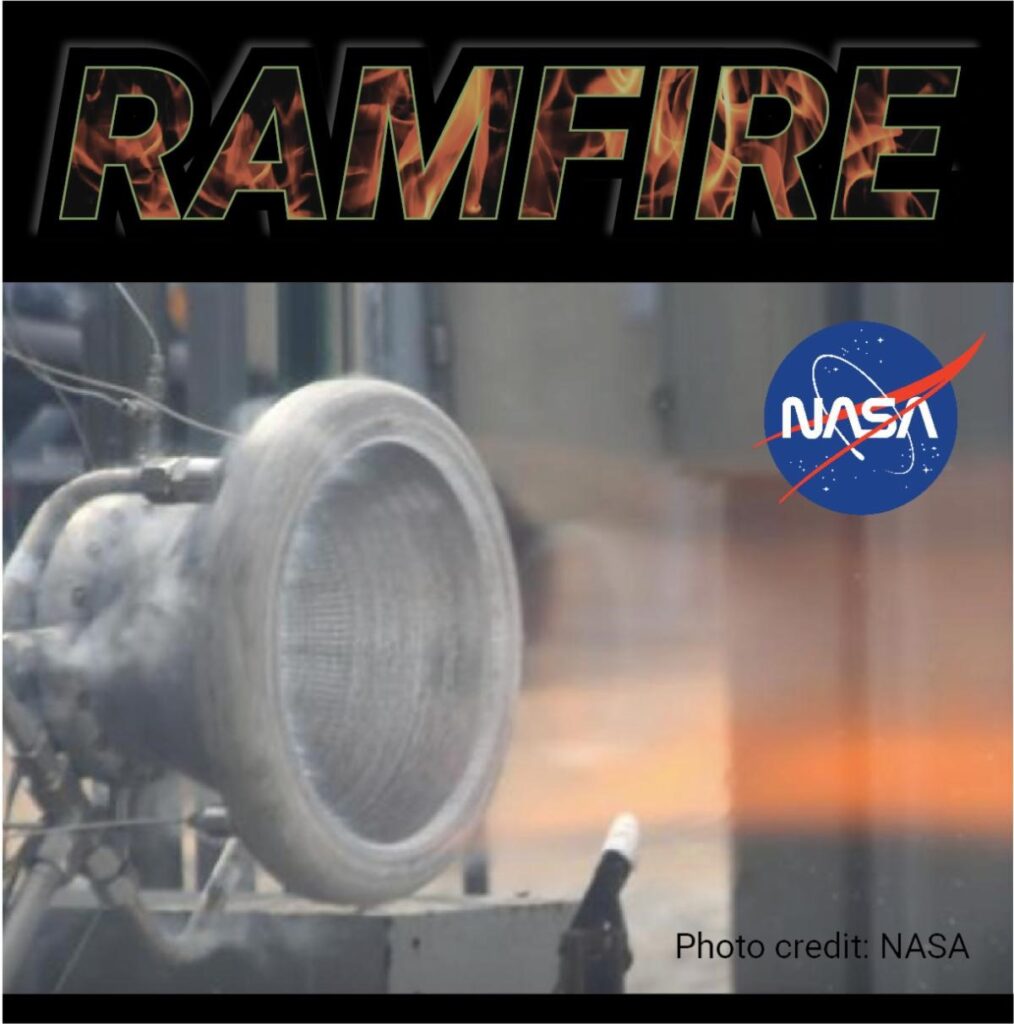

A6061-RAM2 powder to expand space travel frontier

On October 20, 2023, NASA notified the world of the successful testing of a rocket engine manufactured by 3D printing with aluminium A6061-RAM2 powder (full article)(video). NASA’s Reactive Additive Manufacturing for the Fourth Industrial Revolution (RAMFIRE) project has focused on advancing lightweight, additively manufactured aluminium rocket nozzles since November 9, 2020, when NASA announced the U.S. companies selected for partnership through their Announcement of Collaboration Opportunity (ACO) program. Elementum 3D was selected as one of 17 companies to rapidly mature space technologies.

The A6061-RAM2 printed rocket nozzle was developed through the collaboration of NASA engineers at Marshall Space Flight Center and Elementum 3D. The optimisation of material performance and reduction of cost for large-scale complex rocket components and launch structures were accomplished through the collaboration of Elementum 3D and RPM Innovations, a blown powder direct energy deposition (DED) company.

NASA reported that the RAMFIRE Project completed multiple hot-fire tests with pressure chambers more than 825 pounds per square inch (psi). The nozzles proved to be heat resistant enough to successfully accumulate 22 starts and nearly 10 minutes of run time, demonstrating their capabilities in the most demanding deep-space environments.

NASA’s collaboration with the team at RPM Innovations and Elementum 3D is helping to increase the confidence of other aerospace companies in novel high-performance alloys and the flexibility of the blown powder-DED additive manufacturing process.