Design for Additive Manufacturing

(DfAM) doesn’t have to be a mystery, or a significant barrier to using AM as a production solution. It could be a lot easier than you think.

4 things you should know about Designing for Additive Manufacturing

1

Most, if not all, manufactured parts are designed in a Computer Aided Design (CAD) software application, and applying AM specific rules is very simple.

2

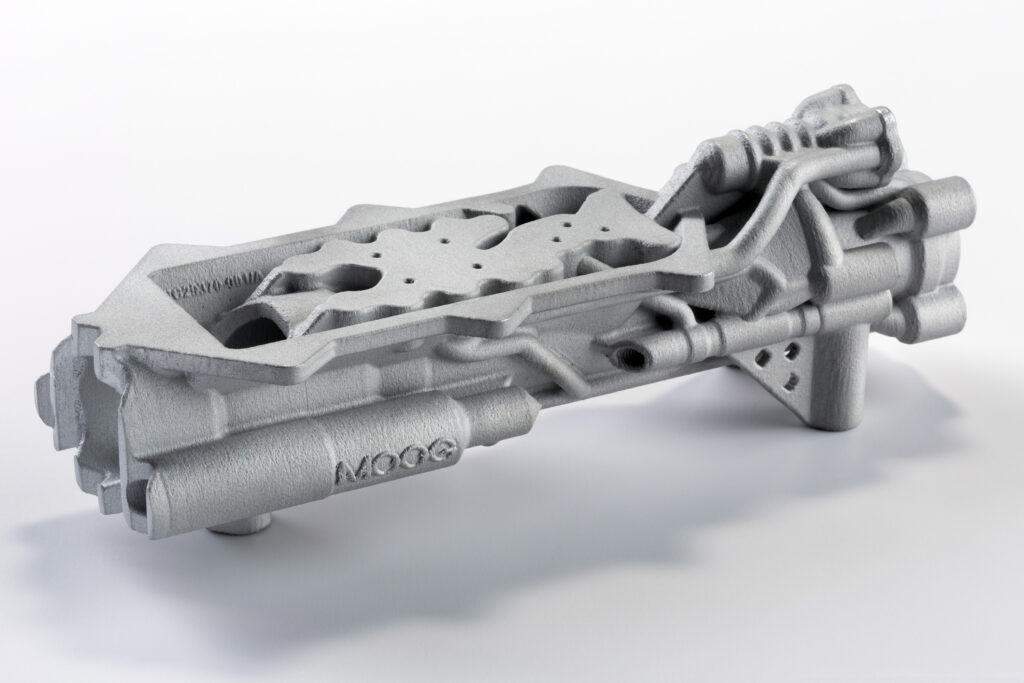

“Complexity is for free” – Oh no it is not!

So many people make this claim, and it is simply not true. Complex parts can be very demanding, both in design and in the manufacturing processes.

3

Design rules for these types of manufacturing processes vary depending on the exact AM technology that will be deployed, and some “golden rules” are not so fixed.

4

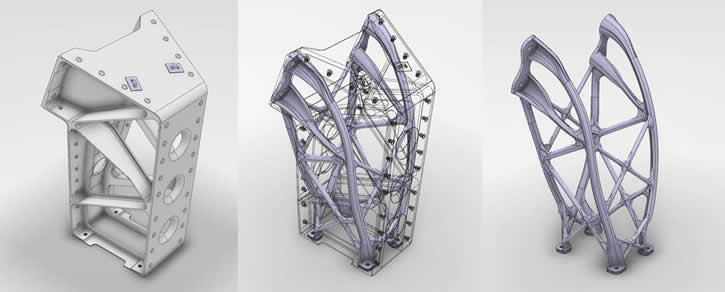

Topology Optimisation is not designing for Additive Manufacturing. Neither is simply taking weight out of a part, or combining many parts into a single component.

Going with the flow

It sometimes only takes very minor changes to a design, or perhaps just a slightly different way of looking at the part in terms of manufacturing orientation that will enable you to build a great part.

Trusted experience

Having been one of the first to deliver dedicated commercial DfAM training anywhere in the world, Martin is here to help you to understand what you’ll need, where to find the resources, and how to accomplish the all important first steps to designing the right parts for a successful outcome.